by John A. Pawlowski, Sr. for Connecticut Explored

When we think of Connecticut’s abundant natural resources, our state’s lakes, rivers, forests, and shorelines come readily to mind. But Connecticut also has a complex and compelling geologic legacy that provided our forefathers with substantial mineral riches. In particular, Connecticut’s veins of pegmatite have historically been a boon to industry and allowed the small state to contribute mightily to the national defense.

Pegmatite, a granite-like rock made up chiefly of feldspar, quartz, and mica, was formed by magma, or melted rock, that squeezed its way between layers of existing rock. Unlike lava, it remained below ground, never erupting through the surface. Pegmatite can be either simple or complex depending upon the chemical elements in the molten rock of which it is made. A pegmatite containing such elements as beryllium, boron, lithium, or uranium may yield stores of exotic minerals that are both beautiful and economically valuable. A few of the several dozen pegmatite quarries in Connecticut achieved world fame as rich sources of these species. Several minerals, including columbite, which in the 1600s became the first new mineral discovered in the United States, were discovered in Connecticut pegmatite rocks.

Pegmatite was first mined in Connecticut sometime before 1825, when the first feldspar mill began operating in South Glastonbury. Most of the pegmatite quarries (open pit mines), were located between South Glastonbury and Haddam Neck on the east side of the Connecticut River, and from Middletown to Haddam on the west side of the river. New Milford, Southford, and the Branchville section of Redding also contain important Connecticut pegmatite deposits.

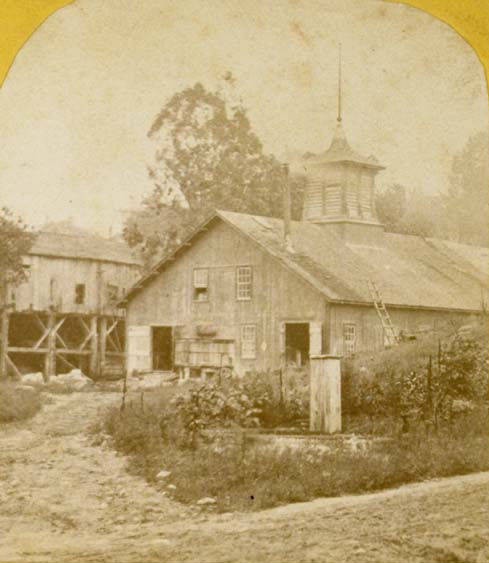

Brainard & Cooke Feldspar Mill, Higganum – Connecticut Historical Society and Connecticut History Online

Versatile Feldspar

For centuries pegmatite was chiefly valued for its mineral feldspar. Feldspar mining peaked in Connecticut in the early 1900s; in 1908 Connecticut, with its four “spar” mills, was the leading producer of this mineral in the United States.

To collect feldspar, miners would drill holes in the pegmatite, fill them with black powder or dynamite, and blast the rock into chunks. The miners then chipped unwanted minerals attached to the feldspar—or, as they called it, “spar,”—off with hammers, in a process known as hand cobbing. Even after new technology made it easier to separate the valued mineral from the refuse, hand cobbing remained standard until the 1930s. The spar was transported by wagon to a mill for further processing before being loaded on schooners or rail cars and shipped to manufacturers.

The first feldspar mill in the state was operated by John C. Wiarda in South Glastonbury. All the early spar mills were water-powered chaser mills. The spar was shoveled by hand beneath two vertical, moving stone wheels called buhrstones, whose great weight crushed the chunks to a fine powder as they rotated around a stone base called a chaser. Eventually tube mills were used for finish grinding. Tube mills consisted of steel cylinders revolving on a horizontal axis. The interior of the cylinder was lined with either hardwood or stone. The feldspar was pulverized by flint cobbles as the cylinder turned.

Connecticut’s Quarries Yield Consumer Goods

Industry demanded good-quality feldspar for making porcelain pottery, vitrified sanitary ware (sinks and toilets), enamelware, glass, poultry grit (which was fed to chickens to help them process food in their crop), abrasives, and fertilizer.

Perhaps the most famous feldspar-based product is Bon Ami cleanser, which features the relatively soft mineral as a mild abrasive. In 1885 mineral-soap pioneer J.T. Robertson opened his first factory, in Glastonbury. He founded the J.T. Robertson Company to produce his soap and moved to Manchester in 1891. The Child & Child Company of New York City, which served as Robertson’s selling agent, obtained a five-year option to purchase the manufacturing rights in 1893, and the Bon Ami Company was formed. Initially all the feldspar the company used came from Connecticut; later, much of the feldspar was imported from New Hampshire and Canada because it was cheaper. The Manchester plant continued to manufacture Bon Ami until the late 1950s. Today Bon Ami is produced by the Faultless Starch Company of St. Louis, Missouri.

Multi-tasking Mica

While feldspar was the most sought-after mineral mined from pegmatites, quartz and mica also had important industrial uses. Mica is the common name for a group of chemically related minerals sharing a property that allows them to be split into thin, flexible sheets. Muscovite mica, one of the more common species in that family, can occur in sheets more than three feet wide. Muscovite has two additional properties that make it industrially important: its high melting point, and it’s very high electrical resistance, which makes it a good insulator. Muscovite could be split into thin sheets and used in place of window glass, a practice that continued in some locales into the 20th century. Furnaces and wood stoves often feature windows made of muscovite, whose high melting point makes it well suited to that application.

With the dawn of the age of electronics mica found new use as an electrical insulator in vacuum tubes, capacitors, and other electronic devices. During World War II muscovite was extremely important to the war effort, and many of the pegmatite mines in Connecticut were prospected for mica instead of feldspar. You probably have mica in your home: It insulates the heating wires in toasters and hair driers. Pulverized mica has been used as a dry lubricant, artificial snow, and for windows in the convertible tops of Model Ts. Today mica adds glitter to stucco wall finish and to cosmetics.

Lepidolite, a member of the mica group, contains the element lithium, which beyond lending a nice lavender or purple color makes lepidolite a worthwhile mineral to mine. Lithium is the main ingredient in a medication used to treat manic depression. This element is also used in special lubricants, batteries, and in alloying metals. The Swanson Mine in East Hampton is rich in lepidolite. During World War I approximately 40 tons of lepidolite was stockpiled at the mine until there was enough to ship, and the United States government feared that it was to be shipped to Germany. For some unreported reason, the ore never left the docks.

Lithium-containing pegmatite can give rise to many rare and unusual minerals. One of the more important of these is the gem tourmaline, or elbaite. In Connecticut this mineral occurs primarily in the colors pink or green. Three quarries in the Portland region have yielded beautiful elbaite gems: the Bract Prospect in Glastonbury, Strickland Quarry in Portland, and the Gillette Quarry in Haddam Neck. Tiffany & Co. of New York City hired local miners to man the Gillette Quarry operations.

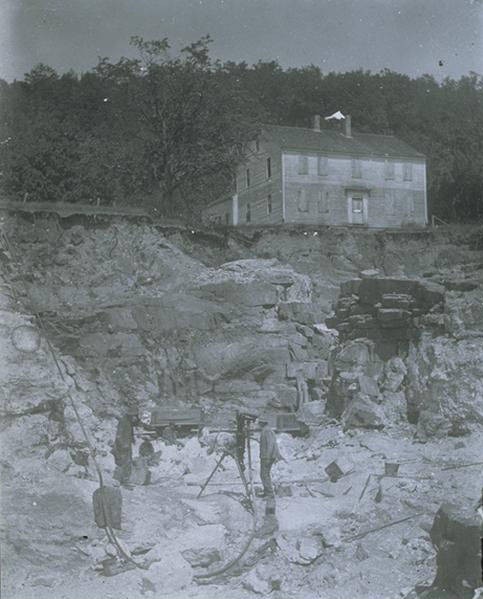

Bridgeport Wood Finishing Company, Branchville – Brent M. Colley

Diverse Uses of Quartz

Quartz, another of the primary minerals in pegmatite, is the most common mineral on the earth’s surface. Early Americans mined quartz and fashioned the pieces into very sharp tools such as knives, scrapers, and arrowheads. Quartz came of age during the Industrial Revolution, largely for its role in glass making. Glass is nothing more than a type of melted quartz.

Finely pulverized quartz was also used as filler in paint and as an abrasive for finishing wood and metal. Two plants, both operated by the Bridgeport Wood Finishing Company, processed quartz from pegmatite mines for these purposes. One plant was located at Lover’s Leap in New Milford and the other in Branchville. The ruins of the New Milford operation can be visited at the recently opened Lover’s Leap State Park.

Beryl’s Double Life as Gemstone and Nuclear Component

Another important industrial mineral found in pegmatite is beryl. Beryl is the common name for a family of minerals whose main difference from one another is color. Most people will recognize members of the beryl family by their individual names such as aquamarine, morganite, heliodor, and emerald. Any member of the beryl family can be considered a gemstone if it has the fine qualities needed to make jewelry.

Beryl, Middlesex County – Yale Peabody Museum of Natural History

But beryl’s not just about beauty. During World War II and through the 1950s beryl became the most sought-after mineral in pegmatites. Beryl is the primary ore of the element beryllium and is used as an alloy in copper and other metals and for control rods in nuclear reactors. Tons of industrial-grade beryl were mined in Connecticut, mostly for use during World War II and the Cold War years.

Many Connecticut pegmatite mines produced gem beryl. Probably the best known of these, the Roebling Mine in New Milford, was worked for feldspar, mica, and, from the 1880s to 1900, for gem-quality beryl. During those years Tiffany & Co. bought more than $17,000 worth of rough, uncut gems from this mine.

Other gem-producing mines were the Southford Pegmatite mine in Southbury, which yielded beryl crystals measuring more than two feet in diameter, many of them featuring gem-quality areas. This mine opened in 1906 and operated until the late 1920s for quartz. It was then mined for beryl during the 1940s and 1950s, when the mineral was classified as a strategic ore.

During the 1950s and 1960s, Howard Hewett mined the Turkey Hill Quarry in Haddam for gem beryl, yielding many thousands of carats of aquamarine. There are a number of abandoned pegmatite prospects in the Haddam area where gem beryl has been found long after Hewett ceased mining there.

The Gillette Quarry in Haddam Neck has also yielded a substantial quantity of gem beryl, mostly goshenite (colorless), aquamarine (blue), and morganite (pink). Morganite was named after the financier J.P. Morgan, one of the benefactors of the American Museum of Natural History in New York City, who donated many Gillette Quarry gemstones to the museum.

Gillette Quarry, Haddam, ca. 1890 – Connecticut Museum of Culture and History. Used through Public Domain.

Pegmatite can contain many other, less familiar minerals. In 1878-79 seven new species were discovered in a quarry in the Branchville section of Redding that was being mined for mica and feldspar. The mine owner sent these minerals—dickensonite, eosphorite, fairfieldite, fillowite, lithiophylite, reddingite, and triploidite—to Yale University for identification. Since their initial discovery these minerals have been found in many places around the world; however, none are industrially important.

With the end of World War II, there was no longer a critical demand for the strategic minerals found in pegmatite. The Feldspar Corporation was the sole survivor among Connecticut’s pegmatite producers, mining both the Hale Quarry in Portland and the White Rocks Quarry in Middletown. To help make the operation profitable, the Feldspar Corporation mined both quarries for quartz and mica, as well as feldspar, and used the flotation separation technology developed in the 20th century that allowed minerals in pegmatite to be sorted more easily and cost effectively.

The feldspar from Hale Quarry and White Rocks Quarry was sold mostly to the ceramics industry, while the quartz went to the Anchor Glass plant in Dayville, Connecticut. The mica was sold to manufacturers of spackling compounds for wall board, asphalt roofing shingles, and cosmetics and toothpaste. When the Feldspar Corporation closed its Connecticut Division for economic reasons in January 1991, nearly two hundred years of pegmatite mining in Connecticut ceased.

Pegmatite continues to be mined in other areas in the United States and throughout the world; in fact, the Feldspar Corporation is still in operation in its home state of North Carolina.

Museums, Not Mines, Best Place to Find Pegmatite Today

Commercial demand may have waned, but interest in pegmatite remains strong among mineral collectors, who probe the walls of quarries and dig through the tailing spiles, or waste rock, searching for any rare or interesting minerals that may have been overlooked or discarded. Once in a while someone finds a real “gem.” A mineralogist studying pegmatite today can learn a lot about its complex chemistry, leading perhaps to a clearer understanding of its origin and age. With luck, one might even discover a new mineral in these abandoned quarries.

But hunting pegmatite minerals in Connecticut is a challenge, as a number of quarries have been filled in, and others stand on private property and are therefore not accessible. The Strickland Quarry in Portland is now a golf course, while the White Rocks Quarry in Middletown was the site of the disastrous Kleen Energy power-plant explosion in February 2010.

The Connecticut Department of Environmental Protection owns several abandoned pegmatite quarries and allows mineral clubs access for collecting on a limited basis. The rest of us can simply keep our eyes open, checking construction sites or examining rock cuts along highways.

But the simplest, most foolproof way to study Connecticut’s pegmatite minerals is to visit a museum such as the Connecticut Museum of Mining and Mineral Science in Kent or the Peabody Museum of Natural History in New Haven. You will be amazed at the riches that could well be found beneath your feet.

John A. Pawlowski, Sr., a geologist and earth sciences teacher (now retired) by training, is director of the Connecticut Museum of Mining and Mineral Science.

© Connecticut Explored. All rights reserved. This article originally appeared in Connecticut Explored (formerly Hog River Journal) Vol. 8/ No. 3, Summer 2010.

Note: ConnecticutHistory.org does not edit content originally published on another platform and therefore does not update any instances of outdated content or language.